BOOKMARKS PRINTED ON ARAB TREADLE PRESS

- Richard Kearney

- Jun 24, 2021

- 2 min read

The MOTAT print shop has a tradition of printing bookmarks. From the classic designs for visitors to collect from the take home shelf, to helping visitors to customise one with their own name, the format has been a staple for a while. What I enjoy about the format is its printability on the Arab treadle press, and the small scale allowing for low pressure experimentation with typography design and printing processes.

The process used to print the READ bookmark developed from a solution to a problem from an earlier bookmark. I had designed a bookmark to have a Janet Frame quote printed on it, with a few picture blocks, including one of a long arrow with an asterisk shape on the end. When printed, however, I found that the asterisk had a significant dent and did not print correctly. Rather than redoing the entire design, I decided to keep the arrow, but not print the asterisk end. To do this, I needed to mask off the asterisk – I couldn’t stop it from inking, but I could stop it from printing. This is a technique I picked up when screen-printing, and a digital version of the process now exists in Photoshop. The mask was made from the thinnest material I could find that still had enough rigidity to not flop around, and then attached to the gripper arm on the press, so that as the platen closed, the asterisk was printed onto the mask, and the remainder of the arrow was printed onto the bookmark.

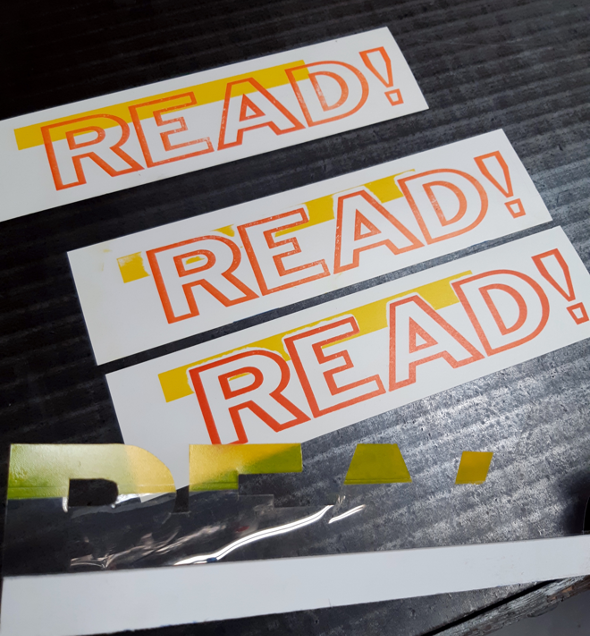

The READ bookmark idea came to me when I was looking at our wooden type collection, and I saw the outline type. I knew from a previous project that we had the long rectangle blocks that I could print, and I thought it would be interesting to have the block go “behind” the outline type – no colour showing through inside. The process started with printing the word on the bookmark, and then carefully tracing the outline of the letters onto the masking material. The mask was carefully aligned and attached to the gripper arm of the press. In the end, a second mask had to be made, as the thickness of the masking material meant that the print of the rectangle wasn’t fully flush with the text, but like all printing, a process of trial and error solved the problem.

Thanks to Scott Pilkington for support on the project with compositing.

-By Richard Kearney

Comments